Remember the last time you talked with someone who had a big dream? Whether starting a business, checking off a personal goal, or anything else—if the dream is audacious enough—you can’t help but want to help them succeed.

That’s even more true if you’ve been friends with that person your entire life. This friend has a big dream: to start a clothing company. Are you ready to join me in making his dream a reality?

Meet Gabe Wallace

Gabe manages IT for trade-shows around the country, but for the last three or four years Gabe has been talking about denim. What started as an interest has turned into a passion (almost an obsession). I’ve been friends with Gabe my whole life. We grew up together. Seeing him care so much about a project—a mission—makes me want to drop everything and help him.

I could spend paragraphs telling you why I am supporting Drift, his new clothing company, but instead I’ll let a video do the talking. Also, keep reading for an interview with Gabe.

Convinced? Ready to join me in helping Gabe’s company become a reality?

Back Drift Republic on Kickstarter »

An Interview

1) What got you interested in jeans, why did you want to start a denim company?

Fit! I’m a 6’1”, athletic-ish guy and I have always had a hard time finding jeans that fit. They would be a little too tight in the waist, too big in the thighs or not big enough for my butt (Yes, I have one :). I’m one of those guys who loves clothes but hates shopping, so I have a bit of a love/hate relationship with fashion.

I often found myself thinking about how nice it would be if there were a reliable source for great fitting clothes sold in a laid back, convenient manner.

I’m a pretty free-spirited guy; I lived out of a backpack for two years in my late teens while bumming around Europe and Africa. Upon returning to the states I helped my uncle build a veggie diesel powered 1968 Mercedes bus to travel and live in. I’ve always known I wasn’t cut out for an 8 to 5 until retirement kind of life.

Having always wanted to work for myself and knowing the best products or services arise when they meet a personal need, I decided I would make my own jeans and make it super easy for guys to buy them.

2) What distinguishes your product from a pair of $30 Old Navy jeans?

Great questions, three main points here:

- Fit

- Quality of our denim and craftsmanship

- Made in the States, by us

We are developing a better sizing model that will include a wide range of sizes, providing a great–almost custom feeling–fit. This is simply not possible with the big brands, whose jeans are designed around broad “averages.”

Our jeans are made in America. From the cotton fields, to the denim mill, to our shop right here in Idaho. When you buy Drift Republic, you know that you are supporting a sustainable, American company providing jobs in your community.

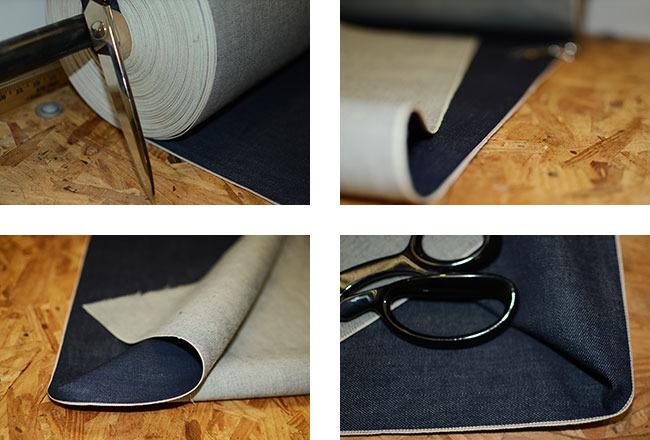

We are incredibly excited to be using Cone Denim; this 13.75oz, raw, selvedge denim is milled at the historic White Oak plant in Greensboro, NC. The White Oak mill is one of the oldest in America, the denim here is still milled on old school, narrow shuttle looms. Producing denim that is only about 31.5 inches wide where as a modern loom is around 69 inches wide. The edges of the denim are sealed closed during the weaving process, creating a self finished edge that does not unravel. This is where the term “selvedge” originated, these beautiful denims are typically heavier, more durable and of superior quality than other denims.

3) Why do you need to raise money, what will your funding go towards?

We are in this for the long haul. We are not aiming to sell or go public so traditional capital models don’t fit our funding needs. Furthermore, if we decide to take a 10% profit loss so we can provide a more sustainable product or a better warranty, we want to be able to make that decision without the approval of a profit-focused board. Due to our relative inexperience in the industry and the youth of our company we would be hard pressed to qualify for a bank loan.

We spent a lot of time thinking about how this would affect us in covering start up costs and cash flow over the first few years. After considering the options we decided to do two things: first we would work solely on developing one product which would enable us to buy a limited number of specialized machines, build a strong relationship with our vendors, and create a truly great product with a clearly defined purpose.

Secondly, we invested heavily from our own savings and bootstrapped any and everything we could without jeopardizing the quality of our final product. As development progressed and we began to turn our attention to building an audience and selling our jeans, we realized we would need a little help getting over the last hurdles to market. We really value our customers. We are building jeans for them, after all, so we thought raising support from them was a great way to bring funds in with a presell model and involve all of you in the development of our jeans and our process.

4) What kind of challenges have you run into?

Wow, what has not been a challenge :) When I started Drift in 2010 I had almost no sewing experience, a $200 sewing machine (that could not sew denim) and no idea where one would go to buy great denim wholesale. With the stubborn determination of an entrepreneur I was able overcome a lot of these challenges. I found dealers for industrial sewing machines and identified the machines we needed. It turns out you need seven different sewing machines to make a high quality pair of jeans. Of these seven we now have five. The two remaining machines we need are a button holer and a chainstitch hemming machine.

This was not without incident, though. The fifth machine we purchased, a waistband sewing machine and our most expensive machine to date at $4,200, was not quite what we expected. We knew it required 240 volt power, so we put in a new breaker and wired up a special outlet just for this machines’ arrival. After pulling the 600 lb beast off the back of a pickup truck with the help of five others guys we wired her up–and blew what seemed like everything! We’re talking smoke, sparks, the whole shebang. After the air cleared and we read the fine print we learned for the first time about 3 phase power. This led to a whole new research project until we found and installed a 1 to 3 phase power converter and motor. Happily, the machine still worked!

It took a little more time but we found and secured some great American vendors for our thread and buttons and we are super excited about using Cone Denim’s White Oak, raw, selvage denim for our jeans. This denim comes from one of the oldest mills in America in Greensboro, NC.

I would have to say that the single biggest challenge has been the pattern development. I have worked in construction since I was a kid, read blueprints and built satellites as a young adult and paid the bills as a web designer, so I figured it wouldn’t be too hard to create a custom pattern. Wrong! Wow, pattern drafting has since been described to me as advanced engineering and I couldn’t agree more. Originally we hoped to be able to develop a truly custom pair of jeans for each customer. This turned out to be cost prohibitive, so we have opted for scaling our pattern to include many more size options than your typical brand supplies. We’ve also given up on tackling this process alone and are on the hunt for a true professional to work with.

5) Do you have a day job? If so, how has this affected the process of building a company?

I do. For the past 6 years I have worked with a managed service company as an account and project manager providing one of the largest IT brands in the world with technical and logistical support for their tradeshows and events. This keeps me on the road a good six to seven months out of the year, a schedule that is both a blessing and a curse!

Development of Drift has been considerably slower than I foresaw. I’ve had the benefit of two great partners, one of whom has since moved on but is still a financial backer of Drift. They have made it possible for work in the shop to continue in my absence, but it’s still a challenge. While on the road I have been able to design and develop our web presence, and write a lot! William and I have really picked up the pace of development in the last two months; we wake up early and work late, something I think any business owner can relate to. :) My family has been of great support and I wouldn’t have it any other way. We feel strongly that building Drift as a liquid company from the beginning is the only way to secure our future. I can’t wait until Drift can provide full time employment, though!

———————

Join the family and back Drift Republic on Kickstarter »

Leave a Reply